avance embroidery machine thread breaks

For more tips and tricks on embroidery visit our blog at httpswwwem. If your Embroidery machine isnt timed appropriately it can cause many problems along with thread breaks.

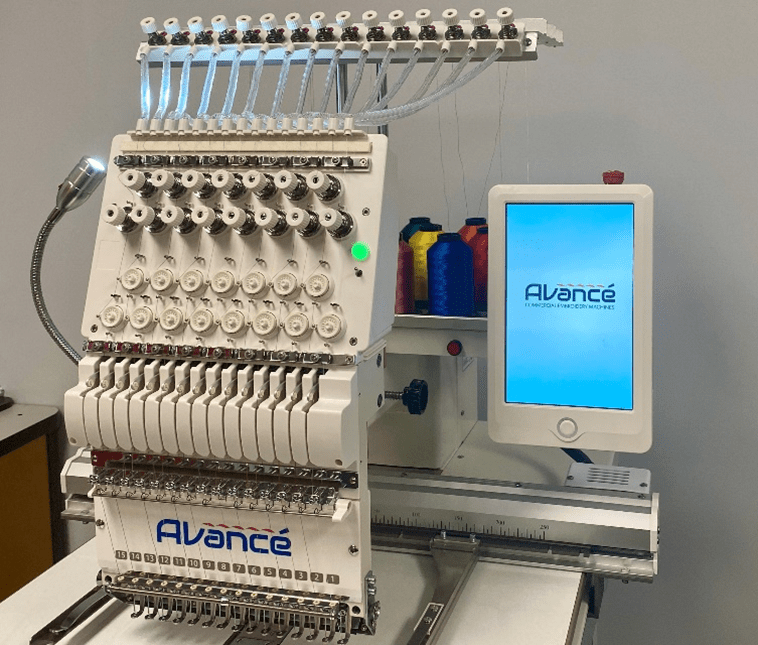

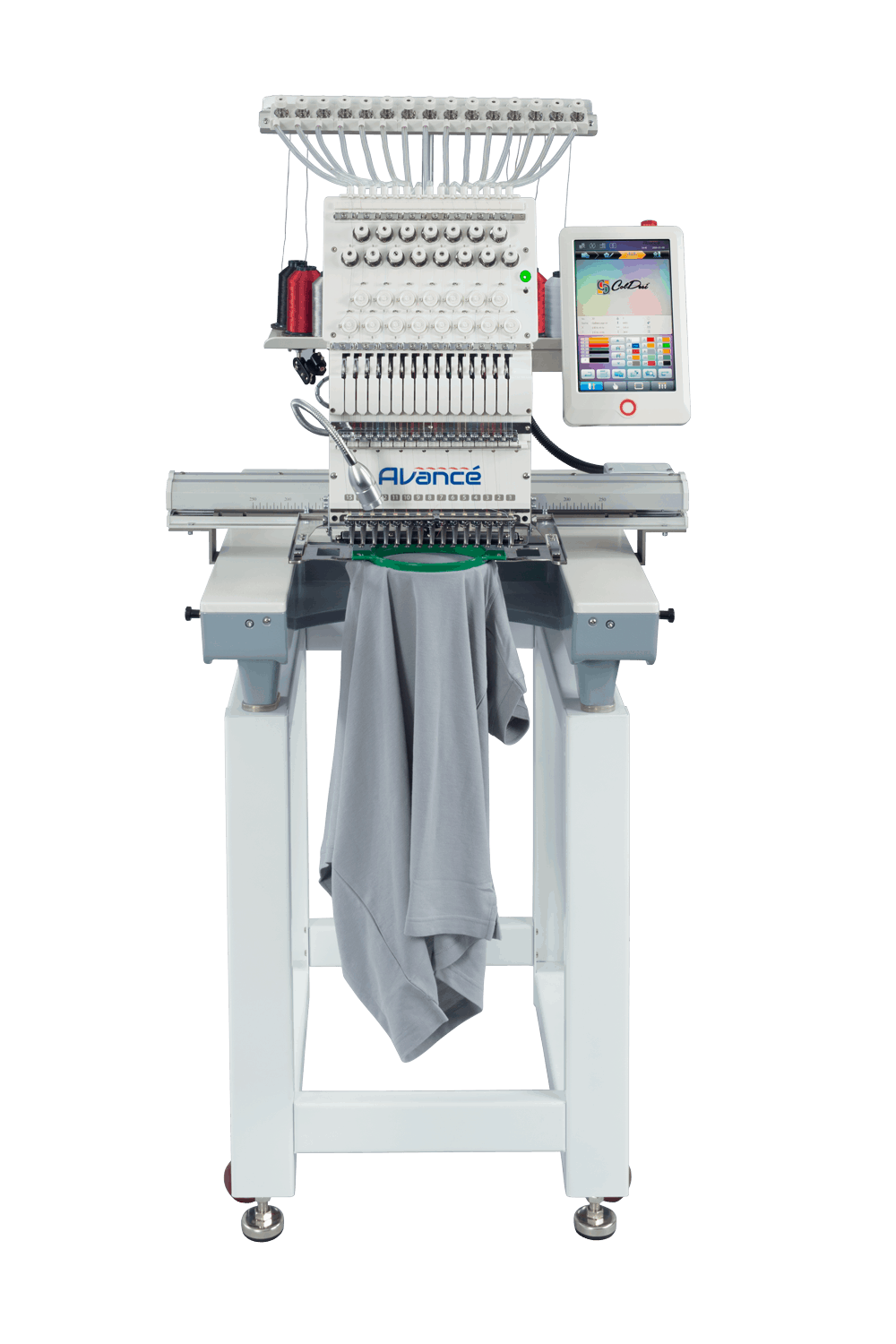

Avance Single Head Embroidery Support

But its useless to be overwhelmed by the matter.

. A high level of upper thread tension or bobbin tension can cause thread breakage. Here are seven 7 of the most common reasons why your embroidery thread might break and how to keep it from happening. Trim the thread to 3-4 cm before inserting the bobbin and case into the hook assembly.

28 on board fonts. Selling 2 Melco Amaya XT machines 2007 with hat frames and carts. June 8 2022 Morehead City NC.

Not good with any other offer. The black pieces on the thread break sensor should pass through the direct center of the metal wheel. Full color touch screen control panel - makes it so simple to use.

The paper comes off as it was put on without issue now. Having thread breaks in an embroidery machine is often a frightening experience. Check that there are no stitches with extremely small pitches in the embroidery details.

If you are using the wrong weight embroidery thread it could be causing your thread to break. Sometimes people forget to thread through. This is a good method to determine what the issue is.

June 13 2022 Sarasota FL. If its slightly off that could cause false thread breaks. Loosening the thread a great deal to begin with and then testing stitches until you reach the right fit is an effective way of finding the best tension level.

This usually happens when youre making a turn at an angle or changing stitches. Use the Troubleshooter below. Avance embroidery machine review.

1 Improper Threading Always make sure that the embroidery machine is threaded correctly. 2 Head 15 Needle Brand New Embroidery Machine. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

If the upper thread misses a point or is not passing through the thread guides smoothly it can break. It can be the cause of a thread break. Flat Head Screw Driver.

Ordinary thread breaks in commercial embroidery can occur anywhere in a design no matter what stitches used. Check your thread weight. Embroidery machines prefer a specific thread weight.

Loosening the thread a great deal to begin with and then testing stitches until you reach the right fit is an effective way of finding the best tension level. Operating an embroidery machine sewing out a design choosing the right supplies are all inter-related. Long tails can cause the bobbin thread to tangle when the machine begins to stitch.

You can schedule training here. Is the thread breaking on just one needle or all needles. Rather than having your thread come off the spool vertically set up the spool horizontally.

For example the Brother PE800 requires 90wt embroidery thread. There may be a chance the sensor was installed backwards or upside down. A change in direction at a corner or a seam can catch the thread causing it to break.

This will prevent the thread from twisting as it comes off the spool. This is the largest showroom of the brand in the MidWest co-located in a 10000 sq ft. While stitching out a job you should have a thread break as soon as the job ends otherwise the job will continue stitching wasting time and material.

If a thread breaks during the restitching process the Avante. If the sensor is installed properly check to make sure it is aligned to the center of the metal wheel. This might be the cause of the upper thread problem with the tiny stitches you should erase.

To illustrate this point think about how toilet paper naturally comes off the roll when laid vertically how it usually is. We only accept substandard machines to part them out. When The Embroidery Warehouse purchases used machines for resell we only purchase the best of the best.

These are some of the major issues for thread breaks in an embroidery machine. Embroidery machines prefer a specific thread weight. We specialize in the reselling of used Tajima Barudan SWF Toyota and Melco among others.

So getting trained one problem at a time is a recipe for frustration not success. Instead you ought to find out how to affect it because it is common to possess thread breaks. Answer yes or no questions and.

A high level of upper thread tension or bobbin tension can cause thread breakage. Thread frays usually have more to do with timing burrs and nicks in the thread path. Plainfield ILIncredible opportunity to own this well established embroidery screen printing and promotional products business.

Check your thread age. The thread break sensor on Avance machines is automatically activated when a thread breaks. Malco Superstar two head embroidery machines 2 June 5 2022 Denver CO.

Avance Embroidery Machine Thread Breaks. So thats 4- 24 heads not working until one thread break is fixed. The most common cause of breaking threads is when the needle catches on the fabric.

They can occur during inching stitches or just after the machine goes to full speed. Thread can get old and brittle. If this is occurring you need to take a look at the way you use your adhesive spray Improper timing.

Deborah Jones shows you what could be causing thread breaks and how to correct them. Check in your manual to see what this weight is. Happy Single Head Embroidery Machine.

This is a good method to determine what the issue is. The reason they do that is simple. We sell just about every make and model of New and Used Commercial Embroidery Machines.

The fix for this problem is loosening the upper tension knob or bobbin. The thread break sensor on Avance machines is automatically activated when a thread breaks. A thread pullout only occurs when the system attempts to start after a trim.

Thread breaks can be caused by tension issues machine timing thread path interference thread caught under spool old or Rayon thread or poor digitizing. Using a flat head screw that was provided to you labeled Minus Driver Small tighten the adjusting screw one to two minutes 1 to the right. If you dont have the skills to resolve the difficulty then it can turn a ten minutes project into an entire hour-long.

An excessive amount of adhesive build-up on the needle can make them drag and break threads.

Monogramming Machine Google Search Computerized Embroidery Machine Swf Embroidery Machine Machine Embroidery

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Avance 1201c Avance Commercial Embroidery Machines

Troubleshooting Embroidery Thread Breaks Youtube

Avance Single Head Embroidery Support

Single Head Multi Needle Embroidery Machine Janome

Commercial Embroidery Thread Breaks True Or False

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Coldesi Inc Announces The Release Of All New Avance Commercial Embroidery Machine News

How To Do Machine Embroidery What You Ll Need To Start An Embroidery Business Avance Commercial Embroidery Machines

Avance Training Repairing A Thread Break Bobbin Run Out Youtube

Setting And Troubleshooting Tensions On The Avance 1501c Youtube

Reduce Thread Breaks Butterfly Embroidery Machine Single And Multi Youtube

Avance Single Head Embroidery Machine Colman And Company

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Avance 1501c Avance Commercial Embroidery Machines

Why Thread Breaks Happen And How To Avoid Them Ricoma Blog

Commercial Embroidery Thread Breaks True Or False

Avance 1504 Multihead Commercial Embroidery Machine Demonstration Youtube